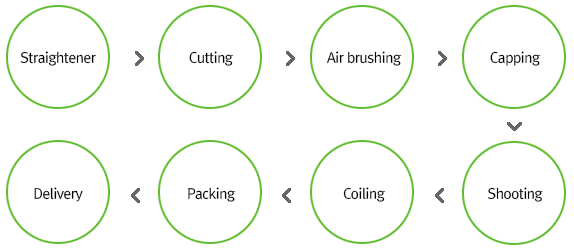

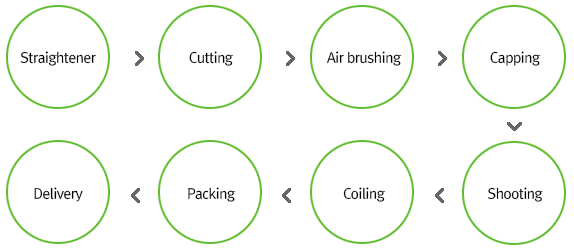

PRODUCTION FLOW

Insulated tube production process

Pass Tube1 PAY OFF

Pass Tube2 PAY OFF

- 1.Straightening

- Process of making copper tubes in line straight to extruder

- 2.Cutting

- Cutting copper tubes to required length

- 3.Air brushing

- Removing foreign substance from inside the copper tube

- 4.Capping

- Capping one end of copper tube to prevent foreign material entering

- 5.Shooting

- Copper tubes inserted into insulation tube

- 6.Coiling

- Finished product coiled

- 7.Packing

- Finished product fixed with plastic bending and packed in plastic to prevent foreign material

- 8.Delivery

- Finished product packed and delivered